All About Injection Mold

Wiki Article

Getting The Injection Mold To Work

Table of Contents6 Simple Techniques For Injection MoldNot known Incorrect Statements About Injection Mold Injection Mold Can Be Fun For AnyoneThe Basic Principles Of Injection Mold An Unbiased View of Injection MoldEverything about Injection Mold

For the mold and mildew supplier as well as the component designer, the specific information from the simulation make their work much easier. Thanks to them, taxing experimental procedures are a distant memory. Improvement loopholes are considerably decreased. For computer system simulations to function and supply sensible results, the computer systems first require a great deal of input.The very same can occur if the version to be determined has actually been simplified a lot on the computer that it does not show reality. Extremely professional injection molding simulation programs therefore consist of extensive databases acquired from numerous dimensions. Above all, this consists of up-to-date material information, which have a considerable impact on the results of the simulation.

Designers or toolmakers ought to additionally, and even must, be totally acquainted with the software application. Service-strong software program producers as a result focus on user-oriented individual interfaces as well as additionally provide easy-to-understand, user-specific as well as interactive training programs. They are also available to respond to inquiries with their know-how (Injection Mold). This is how injection molding simulations make a best component feasible!.

The 8-Minute Rule for Injection Mold

Blog > Advantages & Disadvantages of Reaction Injection Molding by Rimnetics, published on Monday, January 24, 2022 Reaction injection molding (RIM) has actually been made use of to develop components for a large range of various industriescomplex clinical gadgets to building and construction tools. As a lot of item designers understand, the manufacturing procedure you pick will considerably affect the expense, appearances, and also end result of your last product.In doing so, you can best determine which process will certainly best fit the particular needs of your job. Below, we highlight the notable benefits and negative aspects of reaction injection molding to aid optimize your decision-making process.

The mix of polyol and isocyanate produces a fluid with a consistency similar to that of electric motor oil, which permits the mixture to quickly move into every nook as well as cranny of also one of the most complex molds. Therefore, no severe temperatures or pressures are needed to melt as well as create the plastic.

Indicators on Injection Mold You Need To Know

The reduced stress and also temperatures associated with the edge procedure can assist in the encapsulation of a variety of parts, such as antennas, motherboard, magnets, batteries, metal poles, and threaded inserts. Encapsulation can provide various benefits, such as enhanced defense for more delicate parts, burglary avoidance, and decreased parting lines.

Getting The Injection Mold To Work

Edge is even more affordable when it involves creating larger partsespecially in smaller sized manufacturing quantities. In addition to creating majorities, RIM is also fit for developing and constructing get rid of complicated geometries. Reaction shot molding differentiates itself via the high degree of style freedom it supplies. Edge can create components with differing wall densities, curves, and also enveloped elements, among various other desired functions.Because of this, edge is regularly contacted to produce parts for clinical tools and lab tools. The capacity to reduce the number of parting lines on a component is one look what i found more advantage supplied by the response injection molding procedure. As we previously stated, RIM permits suppliers to encapsulate products directly into a part and produce bigger, complicated components in an effective and also affordable manner.

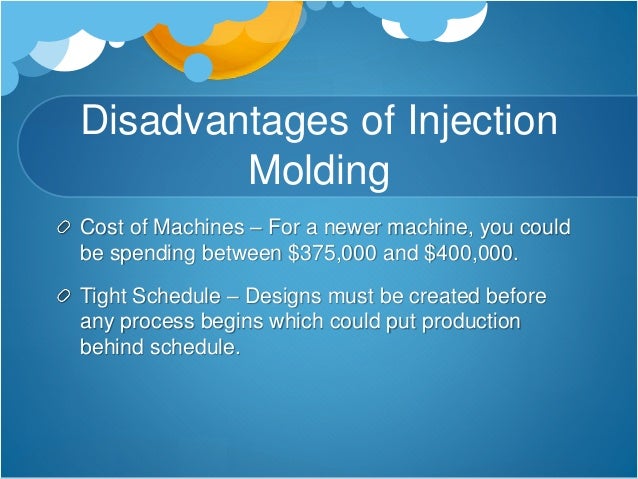

Response shot molding additionally has a few drawbacks. Just like any manufacturing procedure, there are certain applications for which response injection molding may not be ideal. Its downsides are limited, but it's vital to recognize when response injection find more molding might not fit your specific job. Edge normally isn't well-matched for components calling for bigger manufacturing quantities.

Some Known Factual Statements About Injection Mold

If your yearly production volume drops within this range, the considerably lower tooling cost of edge will significantly counter production expenses. Considering that RIM likewise calls for extra ending up and post-molding job, it generally has a slightly greater individual component rate than injection molding. Therefore, when you require to produce components in incredibly high volumes, the greater specific part rates will unavoidably go beyond the cost financial savings provided by a less pricey device.We hope this overview on the major benefits and downsides of response injection molding helps you figure out whether edge is article a perfect technique for your production task. If you think your job might profit from the response shot molding procedure, Rimnetics can help. Rimnetics is North America's leading response shot molding firm for units, cosmetics real estate, architectural components, encapsulation, and also over-molding.

Find out more regarding the top notch edge solutions that Rimnetics provides; contact us today.

What Does Injection Mold Do?

To assist, we have very simply outlined the benefits as well as downsides to think about. Please be conscious, nevertheless, that the following standards relate to what we would consider to be conventional shot moulding (quantities of 100,000+) and may show up initially glance to be fairly prohibitive if you are aiming to establish a product with numbers out of this standard.Additionally, we are specialists in making shot moulding far more inexpensive for much reduced quantities of components than is much more commonly anticipated. Using a crossbreed of methods, our reduced quantity production tooling permits us to personalize to client/geometry/quantities. The result is a mould device that reflects the demand and opens an exciting alternative to produce excellent quality, yet low quantity components.

Report this wiki page